Designing for refurbishment

Rethinking a pressure gauge for a prolongued life cycle

Overview

For this project, I disassembled a digital tire pressure gauge and analyzed its functions, materials and construction aspects. The final aim was to redesign this pressure gauge for the brand Thule based on the disassembled gauge’s internal components. Another challenge was to consider the refurbishment of the product, envisioning a future scenario were the market will appreciate products that are designed, engineered and manufactured for longevity, enabling products to have multiple life-cycles and multiple owners.

Project Info

year: 2020 | 3 weeks

University: Umeå Institute of Design

Methods

brand analysis, ideation sprint, circular design, tear down, mockups testing, parametric modeling.

The design challenge

Design a pressure gauge for refurbishment, thinking about a future where the users will appreciate products that are manufactured for longevity.

Thule | Precision & Durability.

“It is almost always better to reuse products and components than to dispose of (or recycle) them in order to make room for new ones”.

Design is the problem, Nathan Shedorff.

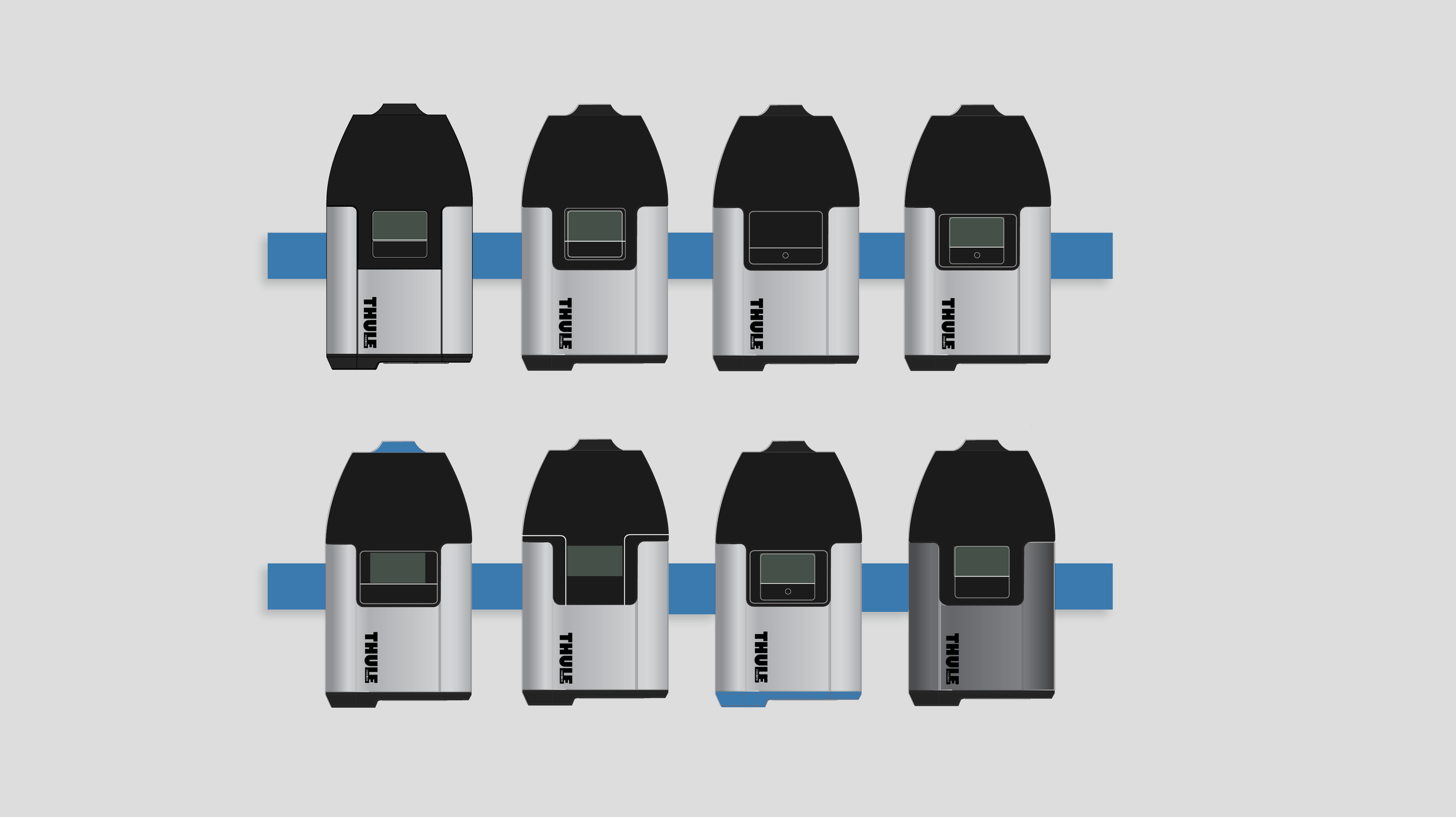

Thule Pressure Gauge

Durability

Few screws

Refurbishment system